Burst Pressure Test Benches up to 15,000 bar (220,000 psi)

Burst Test with (heated) Oil, Water, Brake Fluids, Water Emulsion and more | Fatigue Test | Break Test | Crack Test

In order to prove the quality of the fluid-carrying parts, all hoses, pipes, pressure vessels and other components are put under pressure until they burst. The process is precisely measured and documented in order to optimally design the components for specific applications. The Poppe + Potthoff test benches are equipped with controllable pressure ramps and holding times to suit your specific testing requirements. Our test benches are CE and UL certified and can be adjusted to any type of norms such as ISO, AES and more. Burst tests can be completed for all sorts of components such as pipes, hoses, tubes, oil coolers, valves, hydraulics and various other pressure vessels made of metal, plastics or other materials. Get in touch with one of our experts today.

Especially for your applications

Expertise, proximity to the market and love for the product are our guarantee of success. We are proud of being able to implement leading-edge concepts for testing. We work with our own software applications in LabVIEW and provide you with a highly qualified service team.

For different burst pressure test benches, click the following applications:

Engineering and automotive

In machinery and vehicles fluid-carrying components are exposed to extreme conditions. The capacity of pumps, pressure vessels, tubes and pipes made of metal or plastic is tested by means of dynamic and static pressure tests.

Optional in the climatic chamber

The component tests are requested depending on application with different test fluids under varying temperature conditions. Poppe + Potthoff provides test benches designed for this purpose with quick change device for the test pieces and an optional air chamber.

Performance data:

- Burst pressure from 0 to 4.000 bar

- Fast printing structure and extensive acquisition of measurement data

- Tests at -60 ° C to +180 °C with brake fluid, water, water emulsion or oil

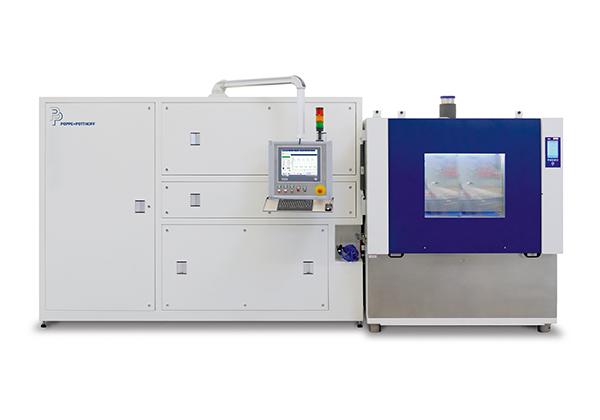

Special Applications

Poppe + Potthoff Engineering develops and manufactures customer-specific equipment for testing items in operation and under fatigue. On these test benches, fittings, hoses and other hydraulic components can be tested until they burst.

Pressure and volume can be precisely increased up to max. 15 000 bar, decreased, or maintained at a constant level. As a specialist for high-pressure applications Poppe + Potthoff offers more performance classes.

Performance data:

- Max. pressure up to 15.000 bar

- 100 000 values measured per second

- Component part tempering -60 °C to +180 °C

- Special technology for extremely large fill and discharge volumes

Plastic components

The test stand is a stand-alone operating system. It was developed specifically for the plastic industry. The test items can be easily adapted with quick connectors. Furthermore, a quick-change device can be used to perform the mountings by testing by hand outside the test chamber.

For the burst test, two test circuits with different working styles are available. Up to 50 bar is possible by the wear-free precision control method, a very precise pressure rise. In another test circuit operates a pneumatically driven pressure translator, with a pressure up to 400 bar can be generated. The test medium is normal mains water or test oil. The test stand can be equipped with a hand-held scanner for identification of the components, thus the burst pressures attributable to each component.

Performance data:

- Burst pressure up to 400 bar

- 0 – 50 bar fine pressure control

- Tests with different fluids and temperature

Pipes and pipe components

Hose, pipes and pipe joints for the industry must safely withstand defined pressures. To test their quality prove they are acted upon by pressure, partly to

failure or bursting.

These test benches of Poppe + Potthoff use a novel technology, which makes it possible to determine burst pressure in just fractions of a second and thus too prove and document the quality of the components used, in the shortest time ed.

Performance data:

- Burst pressure up to 4.500 bar

- Robust test chamber with freely programmable pressure ramp

- Bursting with hydraulically controlled pressure intensifier

Your request

Contact us

Johannes Montag

CEO

Frank Baudler

CTO

Philip Claussen

CEO

+49 3631 46221022

salesppm@poppe-potthoff.com

Philip Claussen

Poppe + Potthoff Maschinenbau America

+1 617 250 7668

philip.claussen@poppe-potthoff.com

For further testing solutions, click the following product areas:

Poppe + Potthoff Maschinenbau is part of the Poppe + Potthoff Group

18 locations in 9 countries.

Poppe + Potthoff Gruppe has 18 production plants and sales offices in 9 countries. The name Poppe + Potthoff always indicates the highest quality – a promise to which our customers rely on, regardless of which Poppe + Potthoff location they work in.